Filtration - Commercial Systems

The chlorine (Bleach) pump is wired to the main water supply pump, so that they work simultaneously, the mixture of bleach and water is retained in the pressure and retention tanks, and then the sediment removal filter so as complete the disinfection of the water.

This pump can be adjusted to deliver the correct amount of bleach, so as to avoid wastage by overdosing, ideal chlorine residual should be 2 parts per million. This is easily tested with a small inexpensive test kit. The quantity of bleach used is determined by the quality of influent water, for example, rain water will use less bleach than well water which contains iron. This is best done by evaluation over a short period of time.

The retention tank is an empty pressure vessel through which the water flows upwards leaving precipitates caused by the bleach/water reaction on the bottom of the tank. These are flushed from the retention tank periodically by simply opening a blow down valve, which goes to waste.

Water then passes into the sediment removal filter via a special valve that consists of four positions;

- “Service” - Filter is in normal operation.

- “Backwash” - To clean filter of accumulated matter.

- “Rinse” - To clear residue after backwash.

- “Brine Rinse” - Only used if filter is configured as a water softener.

The media “Filter Aggregate” removes particulate matter down to the 20-40 micron range. (Human hair is approx. 75 Microns) A more sophisticated combination of media consisting of “Anthracite”, “Sand”, “Garnet” and “Gravel” can remove solids down to 10 microns.

This type of filter is termed a “Multi- Media” or “Depth Filter” The second filter is a “ Granular Activated Carbon” filter, this removes chlorine, odor, taste, color and organics, if present. This filter is usually larger than the sediment removal filter so as to allow more “contact time” for organic removal. Should high quality drinking water be required, we would recommend that an “Ultraviolet” sterilizer or a water distiller be put in place at one faucet preferably in the kitchen so that personnel can use water from one station.

Commissioning and Maintenance

Commissioning involves the filling of gravel bed and media into the tanks and doing the initial backwash to stratify the media. The adjusting of the chlorine injection pump to give a residual of not less than 2PPM. General inspection and remedy of any leaks etc.

Maintenance includes refilling bleach container once a week (bleach should not be exposed for more than this as it starts to lose it's strength). Backwashing approximately twice a month, this is done by opening the backwash line valve and then moving the lever on the filter valve to the backwash position and allowing water to go to waste until it clears up in terms of color, the lever is then moved to the rapid rinse position, there will be an initial flow of dirty water which then clears, the lever is then moved back to the service position, and the backwash line valve closed.

This procedure is repeated on the Carbon filter. This usually takes 20 to 30 minutes for both filters. From our experience we have found that the filter aggregate media should be changed every five years, and the activated carbon every three years, unless there is chlorine residual found after this filter, then it should be changed immediately.

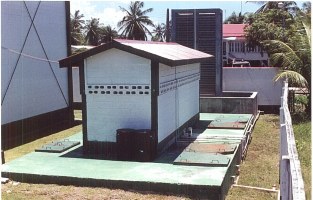

The Bakewell installation at Beterverwagting, design & supply by Spads Inc. constructed by Correia & Correia Construction Ltd.

This system consists of two 15.000 gallon reservoirs and a 5,000 aerator reservoir, raw water stored in the first one is passed through a neutralizing filter then chlorinated on the way to the aerator, level is controlled by a Warrick liquid level control, in the aerator reservoir.

The water, with a 2 ppm chlorine residual, is then pumped by an automatic system controlled by a float valve, through a sediment removal filter to the second storage tank, finally product water is passed through an Activated carbon filter by an "on demand" pump system to the product line and facilities.